Quality control in globalised industries

In global construction, infrastructure and oil and gas industries, access to cheaper, imported building products is widespread. With some subcontractors at times unaware that the products they are installing have been designed to a lower standard than what the contract stipulates, how do we ensure only the highest standards are accepted, so that safety is uncompromised?

Globalisation is allowing organisations around the world to be in dialogue with each other on an hourly basis. Although it is enabling businesses to keep connected from afar, on the flipside it is exposing companies to the lure of cheaper materials, which are sometimes a far cry from the quality products they should be using.

Quality can be neglected in these cases, often as a result of the immense pressures to keep project margins as healthy as possible. This can compromise the soundness of a structure however, which is why it is essential to always select solutions which deliver on quality, ease-of-installation and safety. A tight project timeframe shouldn’t have an impact on the quality of a build.

The need for building quickly and at reduced costs, together with stringent health and safety regulations, means construction companies require access solutions that allow for quick erection whilst maintaining the highest standards. System scaffolding is the best answer to this challenge, and it is something HAKI is well-poised to deliver.

Safety first

The safety-critical nature of the construction industry should mean we need to ensure only the highest standards are accepted, requiring only original manufacturer components to be used. Without safety, there is no product.

Safety and quality are at the core of HAKI’s ethos. As a global organisation these components – along with adaptability and long-term partnerships – are of utmost importance.

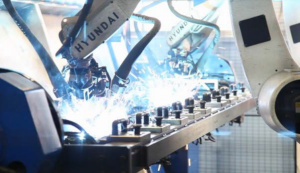

As our products are designed to the highest standards, they enable safe and secure working conditions on all manner of complex projects including oil and gas, infrastructure sites, power generation sites and construction. HAKI’s state-of-the-art manufacturing facilities ensure the safe delivery of large volumes of accurately manufactured scaffolding components. Our products are developed using Finite Element Analysis (FEA); a computational tool which is used to calculate stress, strains and other physical properties. This accurately simulates the behaviour of components to ensure structural integrity is not compromised. The incorporation of this analysis into product development means all components are engineered following reliable and consistent methods.

In addition to computational analysis, all of the products are tested to ensure high strength and durability, while procurement is traced from raw material to finished component. This visibility and thorough testing mentality ensure component quality, which is a huge assurance to our customers. Our products also come with a two-year warranty and comply with the international suite ISO 9001:2008, the standard for quality management.

All of this is done to ensure we deliver what we promise when it comes to providing sophisticated scaffolding solutions.

Installation essential to quality

Quality and safety are integral to the installation stage, as well as product development. HAKI offers a high standard of technical aftersales support to ensure components are incorporated seamlessly into a project’s operations. This level of support works in conjunction with HAKI’s training programmes, which are delivered onsite at its modern facilities.

During construction, HAKI assures all bases are covered when it comes to safety. HAKI’s pioneering temporary access solutions are proven to reduce exposure to falls from height by approximately 60%, according to estimates produced by Park Derochie, the primary distributor of HAKI components in North America. Furthermore, with the simple ‘hook-on’ method characteristic of the HAKI Universal range, hammer swings and repetitive, labour-intensive motions are reduced by 93%. For HAKI, there is no obstacle to safety: it is at the heart of what we do.

Globalisation is serving an important function when it comes to keeping businesses and people connected. The downside to this is the prevalence of cheaper, imported goods which do not meet scrupulous, high standards. It is why it is essential to invest in a company which produces quality products that are at the height of innovation. When safety is at stake, surely no other option can compare?

For more information about quality at HAKI, click here.

Haki has now acquired vertemax – Discover the

Haki has now acquired vertemax – Discover the